5s Kaizen Lean Tools

- The 5S method: This is a systematic approach to organizing and improving the efficiency and effectiveness of a workplace. The five steps of the 5S method are: Sort (organize and eliminate unnecessary items), Set in order (arrange items in a logical and efficient manner), Shine (clean and maintain the area), Standardize (establish and maintain consistent processes), and Sustain (make the improvements a permanent part of the work culture).

- Kanban: This is a visual tool system for managing and improving the flow of work. It uses cards or other visual indicators to signal the availability of materials or the completion of a task, allowing for real-time adjustments to be made to the production process.

- Value stream mapping: This is a graphical tool used to identify and eliminate waste in a production process. It involves creating a visual representation of the process and identifying opportunities for improvement by identifying non-value-added activities and bottlenecks.

- PDCA (Plan-Do-Check-Act) cycle: This is a continuous improvement process that involves planning a change, implementing the change, checking the results, and taking corrective action as needed. It is a systematic approach to problem-solving that helps organizations identify and eliminate root causes of problems.

- Root cause analysis: This is a method of identifying the underlying cause of a problem or issue. It involves systematically gathering and analyzing data, identifying potential causes, and implementing solutions to address the root cause. Common tools used in root cause analysis include the 5 Whys, Fishbone diagram, and Pareto chart.

To use the 5S method, follow these steps:

- Sort: Identify and remove unnecessary items from the work area. This might include items that are not used frequently or are not necessary for the work being done.

- Set in order: Arrange necessary items in a logical and efficient manner. This might involve creating a clear and easy-to-follow layout for the work area, including designated storage areas for tools and materials.

- Shine: Clean and maintain the work area. This might involve regular cleaning to remove dirt and debris, as well as maintaining equipment and tools to ensure they are in good working order.

- Standardize: Establish and maintain consistent processes in the work area. This might involve creating standard operating procedures (SOPs) or visual management systems to ensure that work is performed consistently and efficiently.

- Sustain: Make the improvements a permanent part of the work culture. This might involve creating systems and processes to ensure that the 5S program is consistently followed, as well as training and coaching employees to adopt the new way of working.

Kanban: To use the Kanban method, follow these steps:

- Identify the work process: Break down the work process into individual tasks or stages for your 5s program.

- Create a Kanban board: Use cards or other visual indicators to represent the tasks or stages of the process.

- Establish work in progress (WIP) limits: Set limits on the number of tasks or stages that can be in progress at any given time.

- Monitor and adjust the flow of work: As tasks or stages are completed, move the corresponding cards or visual indicators to the next stage of the process. If a stage becomes bottlenecked, adjust the WIP limits or identify other ways to improve the flow of work.

Value stream mapping: To use value stream mapping, follow these steps:

- Identify the process: Identify the steps involved in the process, as well as the inputs and outputs at each step.

- Create a visual representation of the process: Use a flowchart or other visual representation to show the steps and inputs/outputs of the process.

- Identify non-value-added activities and bottlenecks: Look for opportunities to eliminate unnecessary steps or activities, and identify any bottlenecks that are slowing down the process.

- Implement improvements: Based on the findings from the value stream mapping, implement changes to eliminate waste and improve the efficiency of the process.

PDCA (Plan-Do-Check-Act) cycle: To use the PDCA cycle, follow these steps:

- Plan: Identify the problem or issue to be addressed and develop a plan to address it.

- Do: Implement the plan and gather data on the results.

- Check: Analyze the data to determine the effectiveness of the plan.

- Act: Based on the results of the analysis, take corrective action as needed. This might involve making changes to the plan and repeating the cycle, or implementing a new plan if the original one was not effective.

- Root cause analysis: To use root cause analysis, follow these steps:

- Identify the problem or issue: Clearly define the problem or issue that needs to be addressed.

- Gather data: Collect data on the problem or issue, including any relevant information about the context in which it occurs, the frequency and severity of the problem, and any potential contributing factors.

- Identify potential causes: Use tools such as the 5 Whys, Fishbone diagram, or Pareto chart to identify potential issues.

What is needed in a lean 5S Toolkit

A lean 5S toolkit is a collection of tools and supplies that are used to implement the 5S methodology in a lean manufacturing or continuous improvement environment. Here are some items that might be included in a lean 5S toolkit:

- Floor marking supplies: This may include paint, tape, or stickers to mark out designated areas in the workspace.

- Labeling supplies: This may include stickers, tags, or markers to label items and equipment in the workspace.

- Cleaning supplies: This may include brooms, mops, cleaning solutions, and other supplies to keep the workspace clean and well-maintained.

- Safety supplies: This may include gloves, goggles, respirators, and other personal protective equipment to ensure the safety of employees.

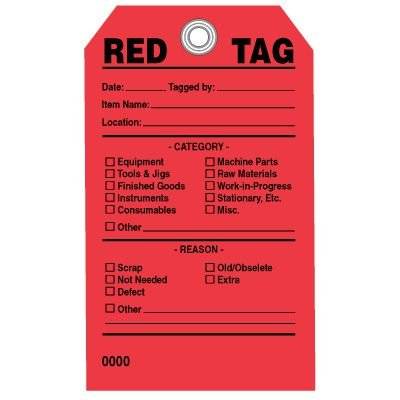

- Red tags: These are tags used to mark items that are unnecessary or have not been used in a certain period of time. They are used during the “sort” step of the 5S methodology to identify items that should be removed from the workspace.

- Green tags: These are tags used to mark items that are necessary and in good condition. They are used during the “set in order” step of the 5S methodology to identify items that should be kept in the workspace.

- Standard work documents: These are documents that outline the procedures and standards for maintaining the cleanliness, organization, and safety of the workspace. They may include checklists, flow charts, and other types of documents.

By having these tools and supplies available, you can effectively implement the 5S methodology and create a more organized, efficient, and safe workspace.

How to run a 5s event

A 5S event is a structured approach to implementing the 5S method in a specific work area. Here are the steps to follow to run a 5S event:

- Identify the work area: Choose a specific work area or process that will be the focus of the 5S event.

- Assemble a team: Gather a team of employees who work in the identified area, as well as any relevant stakeholders or subject matter experts.

- Establish goals and objectives: Clearly define the goals and objectives of the 5S event, including the specific improvements that are expected to be made.

- Conduct a baseline assessment: Evaluate the current state of the work area using the 5S criteria (Sort, Set in order, Shine, Standardize, and Sustain). Document the findings and identify any areas for improvement.

- Implement the 5S steps: Use the 5S criteria to organize and improve the work area. This might involve sorting and eliminating unnecessary items, arranging items in a logical and efficient manner, cleaning and maintaining the area, establishing and maintaining consistent processes, and making the improvements a permanent part of the work culture.

- Evaluate the results: Measure the impact of the 5S event by comparing the work area before and after the event. Document any improvements and identify any areas for further improvement.

- Sustain the improvements: Create systems and processes to ensure that the improvements made during the 5S event are maintained over time. This might involve creating standard operating procedures, training employees, and conducting regular audits to ensure that the 5S principles are being followed.

How to use floor marking during a kaizen 5s event

Floor marking can be an effective tool for implementing the 5S methodology during a kaizen event. Here are some steps you can follow to use floor marking during a kaizen 5s event:

- Identify the areas of the workspace that need floor marking. This may include areas where materials are stored, work stations, traffic areas, and hazardous areas.

- Determine the appropriate type of floor marking to use. Options may include painted lines, tape, or stickers. Consider factors such as the type of floor surface, the level of durability required, and the visibility of the marking.

- Develop a floor marking plan. This may involve creating a layout of the workspace that shows the locations of the floor markings and the purpose of each marking.

- Implement the floor marking plan. This may involve painting lines, applying tape or stickers, or a combination of these methods.

- Train employees on the meaning and purpose of the floor markings. This may involve holding a training session or distributing written materials that explain the meaning of each floor marking and the associated procedures.

- Monitor the effectiveness of the floor markings. This may involve collecting feedback from employees, observing the use of the floor markings, and making adjustments as needed.

By following these steps, you can effectively use floor marking to support the 5S methodology during a kaizen event and create a more organized and efficient workspace.

FAQ:

1. How is 5s used in lean manufacturing

In lean manufacturing, the 5S methodology is a systematic approach to organizing and maintaining a clean, efficient, and safe manufacturing facility.

2. Is 5S a Six Sigma tool?

No, 5S is not a Six Sigma tool. 5S is a methodology for organizing and maintaining a clean, efficient, and safe workspace. It is often used in lean manufacturing and continuous improvement environments as a way to eliminate waste, reduce defects, and improve overall quality and productivity.

Six Sigma, on the other hand, is a methodology for identifying and eliminating defects in a process. It is a data-driven approach that uses statistical analysis and a set of tools and techniques to identify the root causes of defects and implement improvements.

While the 5S methodology and Six Sigma can be used together, they are not the same thing. The 5S methodology focuses on organizing and maintaining the workspace, while Six Sigma focuses on identifying and eliminating defects in a process. Both approaches can be valuable tools for improving efficiency and quality, but they are not interchangeable.

3. Why are red tags used during an Kaizen 5s event?

Red tags are used during a kaizen 5S event to identify items that are unnecessary or have not been used in a certain period of time. They are used during the “sort” step of the 5S methodology, which involves identifying and removing unnecessary items from the workspace.

The purpose of using red tags is to help employees identify items that are not needed in the workspace and to encourage them to make decisions about what should be kept and what should be removed. By eliminating unnecessary items from the workspace, employees can create a more organized and efficient environment that is free of clutter and distractions.

Red tags are typically used in conjunction with green tags, which are used to identify items that are necessary and in good condition. By using both red and green tags, employees can clearly distinguish between items that should be kept and items that should be removed.

Overall, the use of red tags during a kaizen 5S event is a way to encourage continuous improvement and to help employees create a clean, organized, and efficient workspace.