The Kaizen 5S methodology has been extremely popular lately. It is part of the Kaizen management system that helps you to improve the quality and efficiency of your workplace by encouraging you to think about how you can organize your workplace to make continuous improvements. This results in reduced waste, improved communication and increased efficiency. It is most often used in lean manufacturing, but the 5S process is applicable to any work environment, making it a useful tool for managers in any type of industry. The 5S steps was developed in Japan and was identified as one of the techniques that enabled Just in Time lean manufacturing.

The Kaizen 5S process system helps you improve the quality and efficiency of your workplace by encouraging you to think about how you can organize your workplace via small continuous improvements.

Kaizen Events are short duration improvement projects with a specific aim for improvement; typically they are week-long events led by a facilitator with the implementation team

Kaizen 5s In The Workplace

The Kaizen 5S philosophy consists of a five-step process that are used during a Kaizen Event to get an office organized and boost productivity such as your customer service levels

.

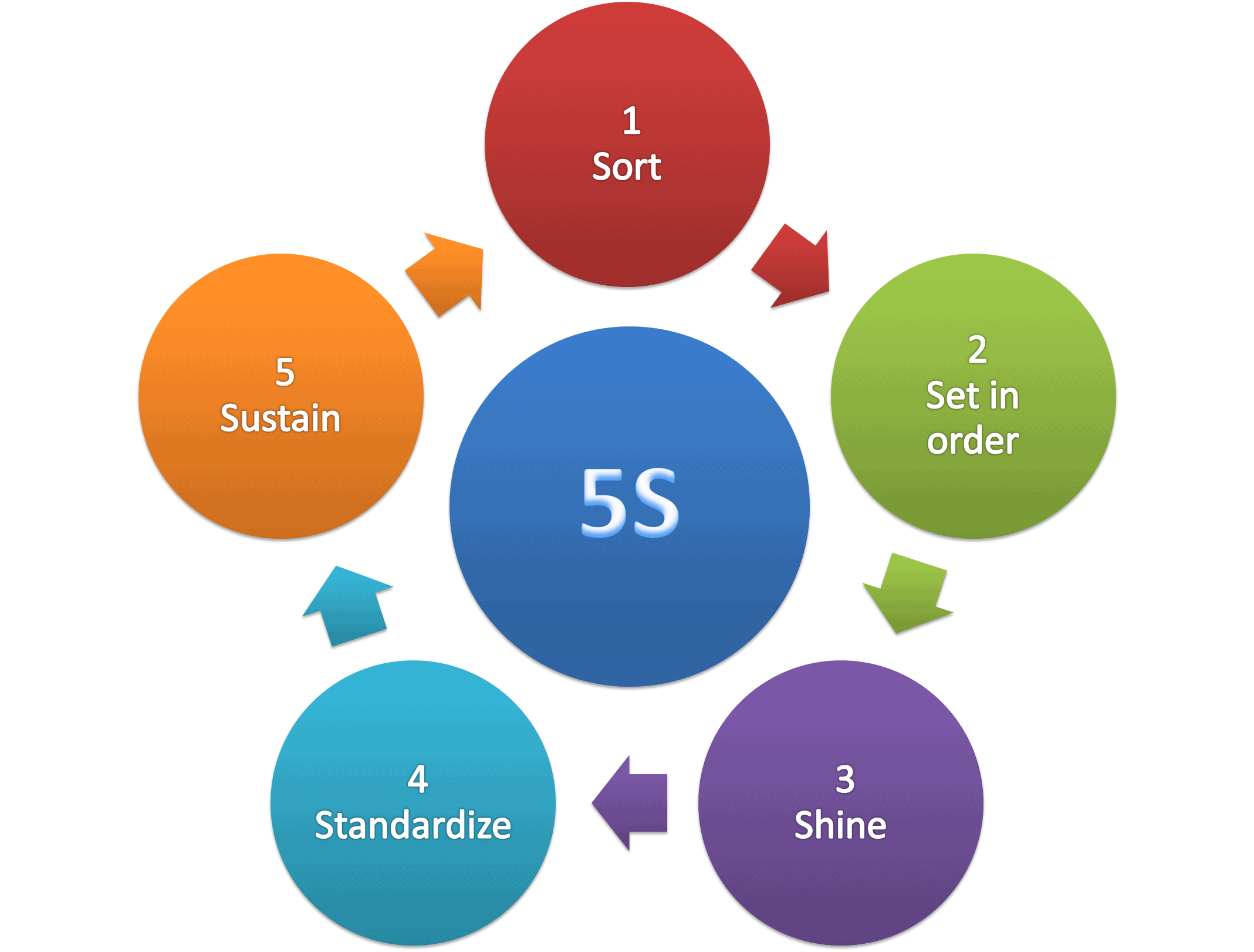

Japanese terms

- Sort (seiri 整理) Get rid of unnecessary things.

- Set in order (seiton 整頓) Put everything in its place

- Shine (seiso 清掃) Clean – create a cleaner work environment

- Standardize (seiketsu 清潔) Set up standard ways of doing things.

- Sustain/self-discipline (shitsuke しつけ) Keep the good habits.

Here’s a great video to get the basic concepts of Kaizen 5S process.

Please visit and support their Youtube Channel Engineering Technology Simulation Learning Videos

Reducing Waste

Organize your office space. Get rid of things you don’t use anymore and unclutter your work area. If your office space is organized, you’ll be more productive and it’ll be easier to find what you’re looking for.When you live in the city or work from home, you always run into distractions like watching too much TV, being distracted by your smartphone all the time, or opening email notifications constantly. If you’re like me and live in the countryside, these kinds of distractions can greatly affect your work. Therefore, it’s crucial to remove them from your working environment.The best way to tidy up your working area is to organize your desk and your workspace – this should be an continuous process.

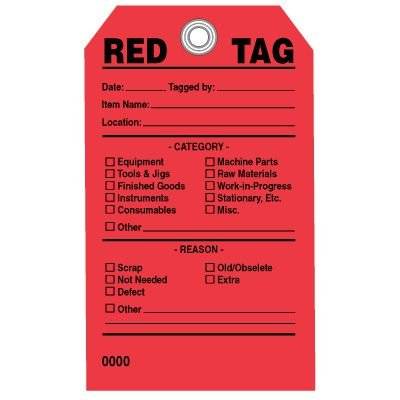

What is A Red Tag Area

When going through the Kaizen 5S process in the “Sort” function, there are sometimes instances where items that should be removed from the facility are kept. A red tag area helpful tool and will help your team temporarily let go of unnecessary items rather than struggle through deciding whether they should be discarded or kept. If you’re anything like me, you’re probably guilty of leaving your pens, papers and other things spread out all over your desk. This may seem harmless enough, but it can lead to chaos. So what’s the solution? It actually is quite simple, you just need a few rules (visual control) to organize your old papers and, hopefully, look nice while you do it. Personal tidying is all about organizing your belongings in a logical and easy way. It might involve throwing out old cupboards, bags and other belongings.

If you “need” something to do with your sorting, then you can ask your immediate work team about donating it. Unexpected items that are not in any obvious place can always be placed into their appropriate place while sorting or donated if the owner chooses so.If you throw things away immediately, it can seem wasteful and therefore unsustainable, but if you sort them into their correct home and label bins, it makes sense.

Improving Communication

Whether you are an administrative assistant or manager of a retail business, you can learn how to utilize the 5S process to improve communication in your organization. 5S is designed to encourage employees to think about how they can avoid creating waste and improve the environment. It encourages them to consider the place where they work, how people communicate and what kind of things are the most effective at increasing or decreasing communication within a work environment. Convey Your Message Effectively Your employees are the face of your organization. Communicating effectively is key for employees to provide a great customer experience. The more effective you are at communicating your message, the better your employees will be at delivering it.

Increasing Efficiency

The 5S process is usually combined with the Do a Dawn patrol, which identifies and resolves problems before they become problems. With a solid 5S system, you will be able to see your workspace from the eyes of a customer. The area that most often contains clutter is the filing cabinets and cupboards in your office. Try separating these two items from your workspace by placing them on a separate shelf from the rest of your desk. By making a good starting point, you are able to clearly see what you have and what you need and communication will become easier. The five senses can be very important to effective communication. When we have too many distractions, we often can’t accurately remember what the other person has said.

Conclusion

Although all of these Lean efforts may take time to implement, these standard procedures are small tasks to improving your productivity, elimination of waste and improve your work environment, which can have great rewards for your company. Making these changes will help you to become a more efficient worker who has better focus, as well as better relationships and team cooperation with your team. You will feel more content with your work, and overall you will have a happier and healthier work environment.

Kaizen 5S FAQ

What is a JIT manufacturing environment?

It’s easier to see problems and move materials efficiently in an environment with an organized workplace that uses visual cues in the manufacturing environment.

JIT manufacturing can proceed more smoothly if there is an organized workplace that uses visual cues to maintain itself.

What is difference between 5S and Kaizen?

Both Kaizen 5S and Kaizen have the same goal of improving processes and reducing waste and are both derived from Japanese concepts.

Some situations will benefit from Kaizen while others will benefit from the organization strategies of 5S, because they have the same end goal.

What is the Toyota Production System?

The Toyota Production System involves a number of methodologies that would become famous in their own right, including Just-In-Time manufacturing, Kaizen 5S, Jidoka, and the core concept of the visual workplace.

The path towards a 5S workplace organizational methodology has been adopted by many manufacturing facilities.

Disclaimer

* Disclaimer (This article contains affiliate links. If you buy a product via this link, it does not increase your costs. On the other hand, it gives you discounts and earns me a small commission which allows me to make detailed reviews like this. )