-

- Jidoka: Quality control at each stage of production so that problems can be immediately rectified.

-

- Kaneko: The quality of the product is guaranteed by our strict quality control system, which includes a series of inspections and tests throughout the manufacturing process. We also have a very strong after-sales service team to help customers with any issues they may encounter.

-

- Just-In-Time (JIT): Produce only what is needed, at the time it is needed, in just enough quantity to meet demand.

-

- 3. Kaizen: Continuous improvement of all aspects of the production process.

-

- 4. Standardized Work: Work processes are clearly documented and followed so that they can be improved upon.

Toyota’s Secret Weapon

TPS has its roots in the early 20th century, when Toyota founder Kiichiro Toyoda developed a set of principles for improving the efficiency of his company’s production operations. These principles were later codified into the TPS, which was formally introduced in the 1950s. Since then, TPS has been continuously refined and expanded, and it is now used by Toyota and other companies around the world to produce quality products and reduce waste (Lean organization).

The Principles

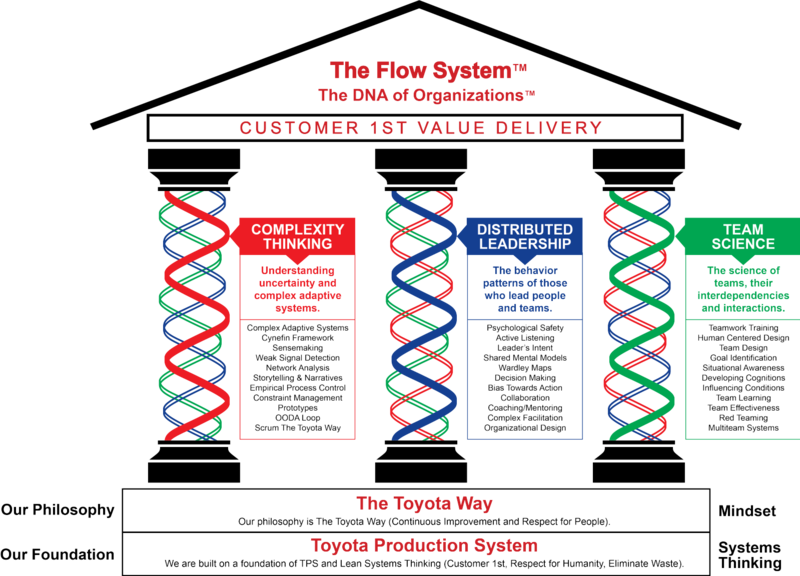

TPS is an integrated system that coordinates all aspects of production, from initial design through to final assembly. The main aim of TPS is to continuously improve production efficiency and quality, while reducing waste and costs. TPS was originally developed by Toyota, and is also known as the Toyota Production System. One of the key principles of TPS is Just-In-Time (JIT)production. This enables the company to only produce what is needed, when it is needed, and reduces the risk of overproduction. JIT production also relies on close collaboration with suppliers, so that materials and components can be delivered just-in-time for assembly. This system has helped Toyota become one of the most efficient and successful automakers in the world. Here’s a few tips to keep in mind: 1. The first step in any process is to identify what needs to be done and who will do it. 2. Make sure that everyone knows exactly what their job is. 3. If there are multiple people doing one task, make sure they know what each other’s jobs are. 4. When something goes wrong, find out why it happened and fix it. 5. Keep your work area clean and organized. 6. Never leave anything half-done. 7. Always finish what you start. 8. Don’t waste time waiting for things to happen; make them happen.Terminology + Lean Tools Used in TPS

The main tool used in TPS is kanban. Kanban is a system used to alert management to problems in the production process. It is used to make improvements and eliminate waste. Kaizen is another tool used in TPS. Kaizen is a Japanese word meaning “continuous improvement.” It is a philosophy that seeks to make small, incremental changes in order to improve quality and efficiency. Kanban is a visual management system that helps teams manage their work and track progress. It’s an effective way of managing projects and resources.

What Makes The Toyota Production System Successful

The key to the successful implementation of the (TPS) is its ability to produce quality goods at a lower price and in less time than its competitors. 1) Just-in-time production: This principle minimizes waste by producing only the necessary amount of product, exactly when it is needed. 2) Continuous improvement: The TPS is constantly evolving and improving, in order to achieve ever-higher levels of quality and efficiency. 3) Respect for people: The TPS recognizes the importance of all employees, from the factory floor to management, and encourages their involvement in continuous improvement. These principles have helped make Toyota one of the most successful automakers in the world. 1. A Good Work Environment. 2. People Who Are Willing To Take Responsibility For Their Actions. 3. An Effective Communication System. 4. A Sense Of Humor. 5. A Sense of Justice. 6. Respect For Others. 7. A Sense of Community. 8. A Sense of Loyalty.Books by Taiichi Ohno

Taiichi Ohno was the Japanese industrial engineer who developed the Toyota Production System, and is considered by many to be the father of the Lean movement. He wrote a number of books on his techniques and philosophy on elimination of waste.which have been translated into many languages. A few of his most influential titles include:

Taiichi Ohno | Toyota Production System

-

- Toyota Production System: A Just-in-time approach to manufacturing.

-

- Toyota’s Secret Weapon: How One Factory Masterminded the Rise of the Global Auto Industry.

-

- The Birth of Lean: How Taiichi Ohno Made Toyota the World’s Fittest Manufacturer.