What is value-stream mapping?

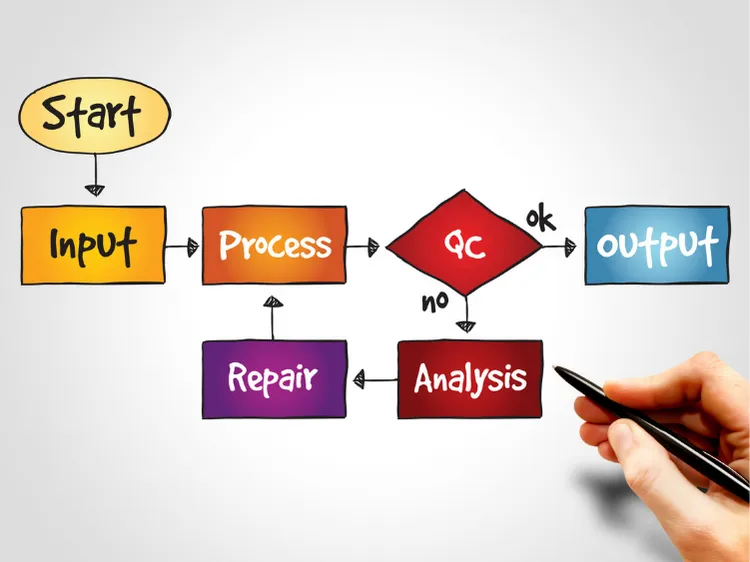

Value stream mapping is a Lean Manufacturing tool that helps identify and eliminate waste in the production process. The goal of a stream mapping exercise is to create a visual representation of the flow of materials and information from supplier to customer. Mapping the value stream allows you to see where improvements can be made to increase efficiency and reduce costs.

In today’s business world, it is essential to have a clear understanding of how products and services are delivered to customers. This is where value stream mapping comes in – an effective tool for improving process and thus creating a higher level of quality and customer satisfaction.

One way to use value stream methodology is to track inventory levels. By understanding how much stock or raw materials are needed at each stage of the process, you can minimize the amount of inventory that is needlessly stored in between steps. This reduces costs and helps to keep the flow of materials moving smoothly.

Continuous improvement is another key benefit of value stream mapping. By identifying and addressing small issues along the way, you can avoid bigger problems further down the line. This helps to ensure that your production process runs smoothly and efficiently, with minimal waste.

According to a study by PwC, 80-90% of tasks in typical business processes are wasteful because they do not add any value for the customer.

Source: (purdue.edu)

Step 1: Decide what to map.

When starting a mapping project, the first step is to decide what to map. This decision can be based on a number of factors, such as the purpose of the map, the audience it will be used by, and the data that is available.

One approach is to start by thinking about what questions you want answered by your map. What are you trying to understand or explain? What are the process times or process steps involved. Once you have a general idea of the questions you want answered, you can start to think about how best to visualize that information in a process map.

Another factor to consider is the scope of your map. What area will it cover? Will it be global or specific to one area? The level of detail you include in your map will also be affected by this decision.

Once you’ve decided on what to map, the next step is gathering data.

Step 2: Collect data.

Collecting data is an important part of any value stream mapping project. The type of data you collect will depend on your research question and the type of study you are conducting. There are several types of data that can be collected, including: primary data, secondary data, quantitative data, and qualitative data.

Step 3: Draw the value stream map.

A value stream map is a great way to visualize the flow of material and information through your process. The map can help you see where there are bottlenecks, identify waste, and find areas for improvement.

Step 4: Analyze the value stream map.

It can help you identify waste and opportunities for improvement. The first step in creating a value stream map is to gather data about the current process. This includes data on the time it takes to complete each step, the amount of inventory at each step, and the amount of waste.

Step 5: Identify improvement opportunities.

Every business has room for improvement. Whether it is a small business or a large corporation, there are always ways to make things run smoother and more efficiently. The first step in improving a business is to identify the areas that need the most attention.

Some factors to consider when identifying improvement opportunities are:

-Areas where sales are down or could be increased

-Costs that can be reduced

-Processes that can be streamlined or automated

-Areas where customer satisfaction could be improved

Once the areas of improvement have been identified, steps must be taken to implement changes. This can be a daunting task, but with careful planning and execution, it can be done successfully.

Step 6: Prioritize improvement opportunities.

There are always areas for improvement in any organization, large or small. However, not all improvement opportunities are created equal. Some should be prioritized over others in order to achieve the greatest impact.

One way to prioritize improvement opportunities is to consider their potential impact on the bottom line. Those that have the potential to increase revenue or reduce costs should be given top priority. Other factors that can be used to prioritize opportunities include their feasibility and how much they will improve organizational performance.

Once the most important opportunities have been identified, the next step is to develop a plan of action for implementing them. This plan should include timelines, resources needed, and who will be responsible for completing each task. Without a plan, most improvement initiatives will fail to deliver results.

Step 7: Implement improvements.

In any organization, there is always room for improvement. Processes can be streamlined, communication can be improved, and tasks can be made more efficient. In order to make these improvements, however, an organization first needs to identify where the improvements are needed. After that, a plan must be put in place to make the improvements happen.

Making changes to an organization can be difficult, but it is often necessary in order to improve performance. Sometimes small changes can make a big difference, while other times more significant changes are required. The important thing is that the changes are made with a clear goal in mind and with a plan for how they will be implemented and measured.

Once the improvements have been identified and a plan has been put into place, it is up to the employees of the organization to carry out the plan and make the improvements happen.

In conclusion, value stream mapping is an important Lean Manufacturing tool that can help identify and eliminate waste in the production process. By creating a visual representation of the flow of materials and information, manufacturers can improve efficiencies and reduce costs.